Air Compressor

BVAdvanced offers a broader selection of compressor lubricants than most suppliers, so our customers have several choices, each with their own advantages within each application area. We cover all air compressor applications, including screw, vane, centrifugal, reciprocating and blowers. Our development engineers have worked with compressor OEMs and engineers to meet the lubricant requirements of modern systems. BVAdvanced lubricants are designed for both standard factory-fill and service-fill applications. Advanced additive technology and the highest quality synthetic-base stocks are used to deliver performance advantages beyond mineral oils and other synthetic air compressor lubricants. The result is safer, more efficient and reliable air compressors. We also offer high performance advanced mineral oil formulations (semi-synthetic) and partial synthetics.

The Synthetics Advantage BVAdvanced air compressor lubricants are based on a wide range of synthetic, partial synthetic and semisynthetic base fluids. Synthetic lubricants offer many significant advantages over mineral oils. These include reduced maintenance, better performance and improved safety. Synthetic lubricants also provide better operation at extreme temperatures, lower volatility, better oxidative and viscosity stability, and cleaner operation. These are benefits that prolong the mainte nance intervals in air compressors. We also offer many selections that are registered for use in food service applications

nance intervals in air compressors. We also offer many selections that are registered for use in food service applications

Longer Service Life, Less Maintenance

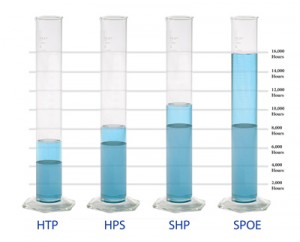

BVAdvanced Synthetic lubricants provide drain intervals several times that of ordinary mineral oils. This is particularly applicable when used in rotary screw compressors where BVAdvanced synthetic lubricants may provide 8,000 – 12,000 hours of service life, or more, when operated in normal environments and operating conditions. Synthetic lubricants will also extend drain intervals for compressors operating at high temperatures and pressures. Synthetic lubricants extend drain intervals and lower lubricant consumption, resulting in fewer lubricant changes. Lower volatility and less lubricant consumption also reduces the risk of vapor fire, while improving the efficiency of aftercoolers.

Energy and Cost Savings

BVAdvanced compressor lubricants offer better viscosity stability, which leads to lower energy costs. Additional efficiency is also achieved through a higher viscosity index, improved heat transfer, or cleaner operation (reduced deposits formation in heat exchangers).

Cleaner, Safer Operation

BVAdvanced compressor lubricants run cleaner, virtually eliminating buildup formation, while reducing maintenance and improving safety. The cleanliness and solvent action our reciprocating compressor lubricants such as BVAdvanced SDE (diester) and SPOE (polyol ester) series lubricants help prolong the maintenance intervals of piston rings and valves. The result is extended maintenance intervals of 2 to 4 times that achieved with typical mineral oils. The risk of fire and explosion is also greatly reduced.

Additional Benefits

BVAdvanced Synthetic compressor lubricants offer many additional advantages, including lower pour points, easier oil/water separation, and easy disposal and biodegradability. One type of synthetic fluid may have specific advantages over another type, but none is superior in all respects. Typically, a compressor application has some requirement or group of desirable properties that contributes to the selection of a particular synthetic lubricant. BVAdvanced offers one of the widest selections in the industry.